How does Extrusion Blow Moulding work?

Author: Scott Jensen Date Posted:5 April 2023

How does Extrusion Blow Moulding work?

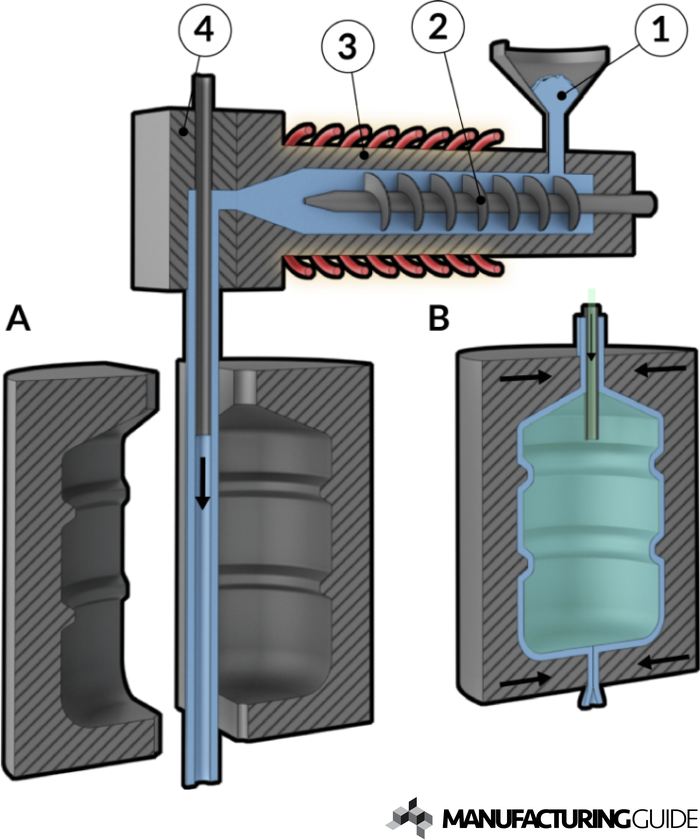

Extrusion Blow Moulding (EBM) is a widely used plastic manufacturing process that creates hollow plastic parts by inflating a hot plastic tube, called a parison, inside a mould cavity. This method is commonly employed to produce a variety of products, such as bottles, containers, and industrial parts. The EBM process involves several key steps, including extrusion, parison formation, inflation, cooling, and ejection.

- Extrusion:

- The EBM process begins with the extrusion of molten plastic, typically a thermoplastic material such as polyethylene, polypropylene, or PVC. The plastic material is first fed into a hopper and then enters an extruder, which consists of a heated barrel and a rotating screw. The screw transports the plastic pellets forward, generating heat through friction and external heaters, which causes the plastic to melt. The melted plastic is then forced through a die at the end of the extruder, forming a continuous tube of molten plastic called the parison.

- Parison formation:

- The parison is extruded vertically downward between the open halves of the blow mould. The length and thickness of the parison can be controlled by adjusting the extrusion speed and die gap. In some cases, a parison programmer may be used to manipulate the parison's thickness distribution, optimizing the final part's material distribution and performance characteristics.

- Inflation:

- Once the parison reaches the desired length, the two halves of the blow mould close around it, sealing the bottom end and capturing the parison's top end around the blow pin or needle. The blow pin injects pressurized air into the parison, causing it to expand and conform to the internal shape of the mould cavity. This step is critical in determining the final product's dimensions and surface finish.

- Cooling:

- After the parison has been inflated, it needs to cool and solidify before being removed from the mould. Cooling is achieved by circulating chilled water or air through channels in the mould walls. The cooling time depends on several factors, including the material's properties, part thickness, and mould temperature. It is essential to optimize the cooling process to minimize cycle time while ensuring the part maintains its desired shape and properties.

- Ejection:

- Once the part has cooled and solidified, the mould halves open, and the finished product is ejected, either by an automatic ejection mechanism or manually by an operator. The excess plastic material, known as flash or trim, is typically removed at this stage, either within the moulding machine or in a secondary trimming operation. The flash consists of the material that has formed around the parting line of the mould and the material that has solidified in the blow pin or needle.

Extrusion blow moulding offers several advantages over other moulding techniques, such as the ability to produce large, hollow parts with relatively uniform wall thickness and complex geometries. Additionally, EBM can accommodate a wide range of thermoplastic materials and is well-suited for high-volume production.

However, the EBM process has some limitations. For example, it may not be the best choice for producing parts with very thin walls or requiring high precision, as the process can lead to minor variations in wall thickness and dimensional accuracy. Furthermore, the method may result in higher material waste due to the trimming of excess plastic.

In conclusion, extrusion blow moulding is a versatile and efficient manufacturing technique for producing hollow plastic parts. By understanding its core principles and optimizing the process, manufacturers can create a wide range of products with unique characteristics and meet the diverse needs of various industries.